- Rumah

- Tentang kita

- Produk

- Berita

- Hubungi Kami

- Rumah

- Tentang kita

- Produk

- Berita

- Hubungi Kami

Menu Web

- Rumah

- Tentang kita

- Produk

- Berita

- Hubungi Kami

Carian Produk

Bahasa

Menu Keluar

A cutting sewage pump is a specialized type of submersible or dry-installed pump designed to handle wastewater containing fibrous, stringy, or solid materials. Unlike conventional sewage pumps, cutting sewage pumps are equipped with sharp rotating blades that macerate debris, preventing clogging and ensuring smooth operation.

These pumps are widely used in municipal wastewater treatment, industrial effluent systems, and residential or commercial sewage networks where clogging due to solid or fibrous waste is a common issue. Their ability to shred materials makes them highly efficient in maintaining uninterrupted flow.

Working Principle of Cutting Sewage Pumps

The cutting sewage pump operates by combining traditional centrifugal pumping principles with integrated cutting mechanisms. The motor drives an impeller that moves the wastewater, while the cutting device shreds large solids and fibrous materials into smaller pieces.

The shredded waste is then discharged safely through the pump outlet, reducing the risk of blockages in downstream pipes or treatment equipment. This principle ensures consistent flow rates and minimizes maintenance requirements.

Key Components of a Cutting Sewage Pump

Understanding the main components helps in selecting and maintaining cutting sewage pumps effectively:

- Motor: Can be submersible or dry-installed; provides the mechanical power for pumping and cutting.

- Impeller: Moves the wastewater through the pump efficiently.

- Cutting mechanism: Rotating blades or grinders that shred solids and fibrous materials.

- Pump housing: Encloses all components and directs flow; often corrosion-resistant material.

- Seals and bearings: Ensure long-term operation without leakage or mechanical failure.

Types of Cutting Sewage Pumps

Cutting sewage pumps can be categorized based on installation, cutting mechanism, and design features.

Submersible Cutting Sewage Pumps

Submersible cutting pumps are installed directly in wastewater pits or sumps. Their sealed motor allows complete submersion, making them ideal for deep sewage tanks or flooded areas. They provide quiet operation and high efficiency in confined spaces.

Dry-Installed Cutting Pumps

Dry-installed pumps are mounted outside the wastewater source, with suction pipes drawing in sewage. These pumps are easier to maintain and are preferred where submersion is not feasible or for high-capacity industrial systems.

Single-Stage vs Multi-Stage Cutting Pumps

Single-stage cutting pumps use one impeller and cutting unit, suitable for standard domestic and light industrial applications. Multi-stage pumps include multiple impellers and cutting units, providing higher head and flow rates for heavy-duty wastewater treatment.

Applications of Cutting Sewage Pumps

Cutting sewage pumps are widely used in diverse applications:

- Municipal sewage systems: Prevent pipe clogging from household and industrial solids.

- Food and beverage industries: Handle fibrous food waste and organic residues.

- Agricultural waste management: Pump slurry containing straw, feed, and animal waste.

- Construction and mining: Manage sludge with solid debris and sediment.

- Residential or commercial sewage lift stations: Ensure reliable flow in sewage networks.

Advantages of Using Cutting Sewage Pumps

Cutting sewage pumps offer distinct advantages over conventional pumps:

- Prevents clogging by macerating fibrous and solid materials.

- Reduces maintenance frequency and downtime.

- Ensures consistent flow rates and efficient wastewater transport.

- Suitable for handling tough waste materials like plastics, textiles, and rags.

- Durable construction capable of operating in harsh environments.

Performance Parameters and Selection Criteria

Choosing the right cutting sewage pump requires consideration of the following factors:

| Parameter | Description | Application Impact |

| Flow rate | Volume of wastewater pumped per hour | Determines suitability for small or large-scale systems |

| Head | Maximum vertical pumping height | Affects pipe design and energy requirements |

| Motor power | Rated power of the pump motor | Ensures adequate torque for cutting and pumping |

| Material compatibility | Resistance to corrosion and abrasion | Extends pump life in harsh wastewater conditions |

| Cutting capacity | Size and type of solids that can be shredded | Prevents clogs and maintains consistent flow |

Maintenance Tips for Cutting Sewage Pumps

Regular maintenance ensures longevity and reliable performance. Key tips include:

- Inspect and sharpen cutting blades periodically.

- Check bearings and seals for wear and replace when necessary.

- Ensure motor lubrication and cooling systems are functional.

- Monitor vibration and noise levels for early signs of mechanical issues.

- Keep the pump and surrounding area free from debris buildup.

Conclusion: Maximizing Efficiency with Cutting Sewage Pumps

Cutting sewage pumps play a critical role in modern wastewater management by preventing clogs and ensuring smooth flow. By understanding pump types, cutting mechanisms, and performance parameters, engineers and operators can optimize selection, installation, and maintenance.

Properly applied, these pumps reduce downtime, increase system reliability, and handle challenging sewage compositions effectively, making them an essential tool for municipal, industrial, and commercial wastewater systems.

Produk Berkaitan

-

Pam edaran berkecekapan tinggi TD menegak dan penjimatan tenaga

Cat:TD Pam Edaran Kecekapan Tinggi Dan Penjimatan Tenaga

Pam edaran saluran paip satu peringkat jenis TD ialah pam emparan sal...

Lihat Butiran -

Pam paip asas mendatar

Cat:Aksesori Pam Saluran Paip

Tapak pam berfungsi untuk menyokong dan mengamankan selongsong pam. T...

Lihat Butiran -

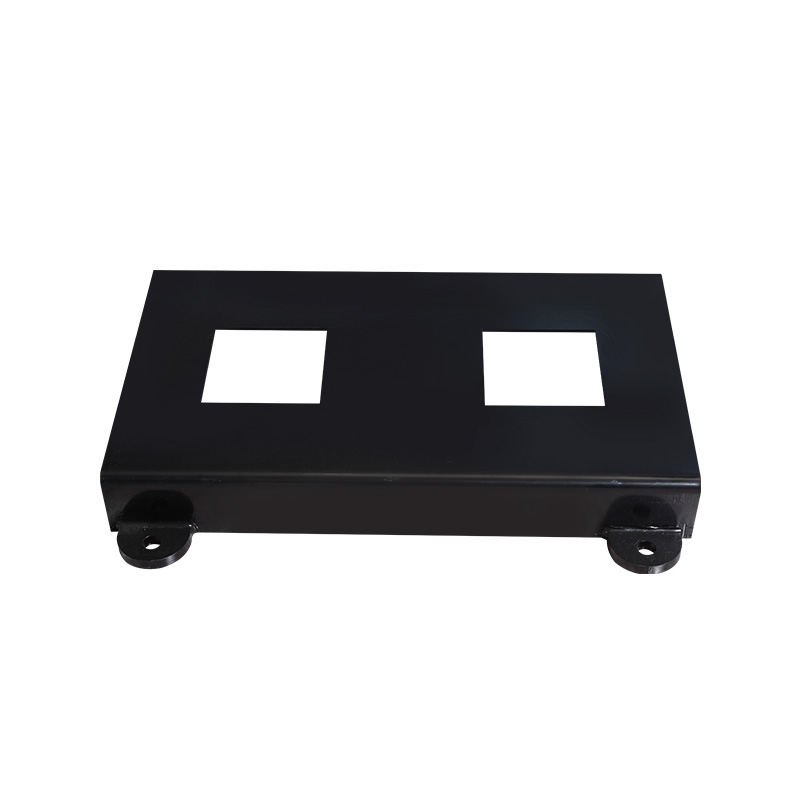

Tempat duduk galas pam kumbahan

Cat:Aksesori Pam Kumbahan

Dipasang di dalam unit pam kumbahan, ia menyokong bahagian pemutar pa...

Lihat Butiran -

LG pam pelbagai peringkat siri 100

Cat:Pam Pelbagai peringkat LG

Ciri-ciri Produk 1. Struktur padat, isipadu kecil, jejak kecil. ...

Lihat Butiran -

LG pam pelbagai peringkat siri 150

Cat:Pam Pelbagai peringkat LG

Keadaan operasi 1. Ia boleh menyampaikan air jernih atau medium ...

Lihat Butiran -

Bahagian salur masuk air pam pelbagai peringkat LG

Cat:Aksesori Pam Berbilang Peringkat LG

Bahagian masuk adalah bahagian masuk pam dan bertanggungjawab untuk m...

Lihat Butiran -

pendesak besi tuang pam pelbagai peringkat LG

Cat:Aksesori Pam Berbilang Peringkat LG

Pendesak besi tuang ialah salah satu komponen utama pam, yang menekan...

Lihat Butiran -

Pemegun siap

Cat:Aksesori Motor Elektrik

Pemegun motor merujuk kepada bahagian tetap yang mengandungi belitan ...

Lihat Butiran -

Pemegun teras motor dan pemutar

Cat:Aksesori Motor Elektrik

Struktur motor biasa, pemegun ditetapkan oleh struktur teras besi, da...

Lihat Butiran -

Motor mendatar

Cat:Motor Elektrik Biasa

Juga dikenali sebagai pelekap asas, motor disambungkan kepada datum p...

Lihat Butiran

-

+86-0563-2251312

-

+86-0563-2251311

-

+86-139 6620 0379

-

-

No.43 Jalan Guohua, Zon Pembangunan Ekonomi Guangde, Bandar Xuancheng, Wilayah Anhui, China

Hak Cipta © Guangde Zhengfu Fluid Machinery Co., Ltd.